Steel: Profile Details

Cold Rolled Steel

Meda exclusively uses cold-rolled steel with Voestalpine profiles for its superior performance compared to hot-rolled steel. Cold-rolled steel offers greater precision, a smoother surface finish, enhanced strength, and improved mechanical properties. Its exceptional dimensional accuracy and consistency are critical for high-performance window and door systems. In addition, the superior surface quality makes it ideal for visible applications, while its compatibility with advanced insulation materials contributes to enhanced thermal performance. These advantages make cold-rolled steel the preferred choice for Meda’s durable, high-quality, and aesthetically refined windows and doors.

Wall thickness is 1.5mm for cold-rolled steel and stainless steel profiles, and 3.00mm for copper profiles.

Various profile developments can meet all kinds of door and window combinations.

Can be used to make windows, doors, partitions, curtain walls, and custom configurations.

Classic and modern designs are all customizable to preference.

Excellent low thermal transmittance, air permeability, water tightness, and wind load resistance.

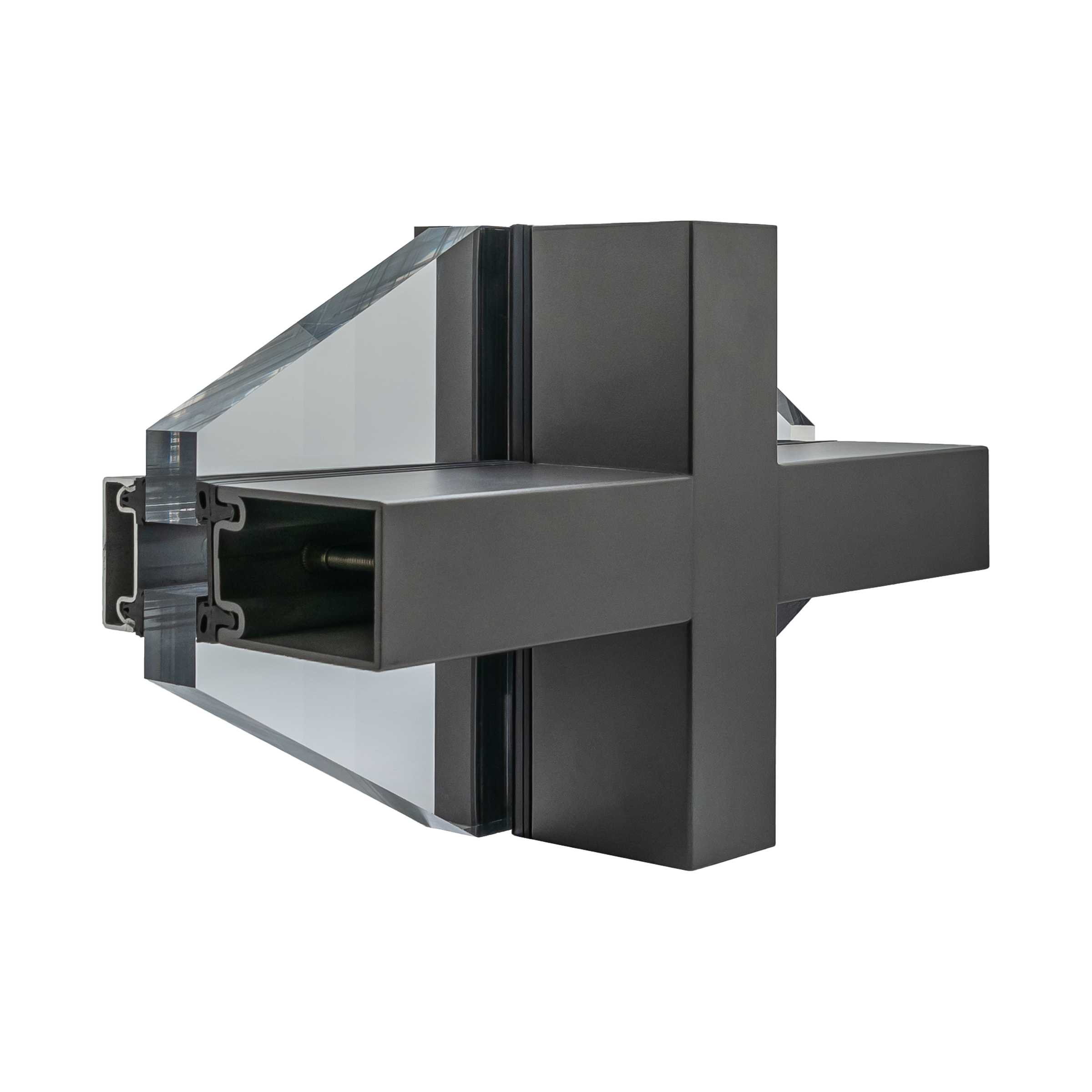

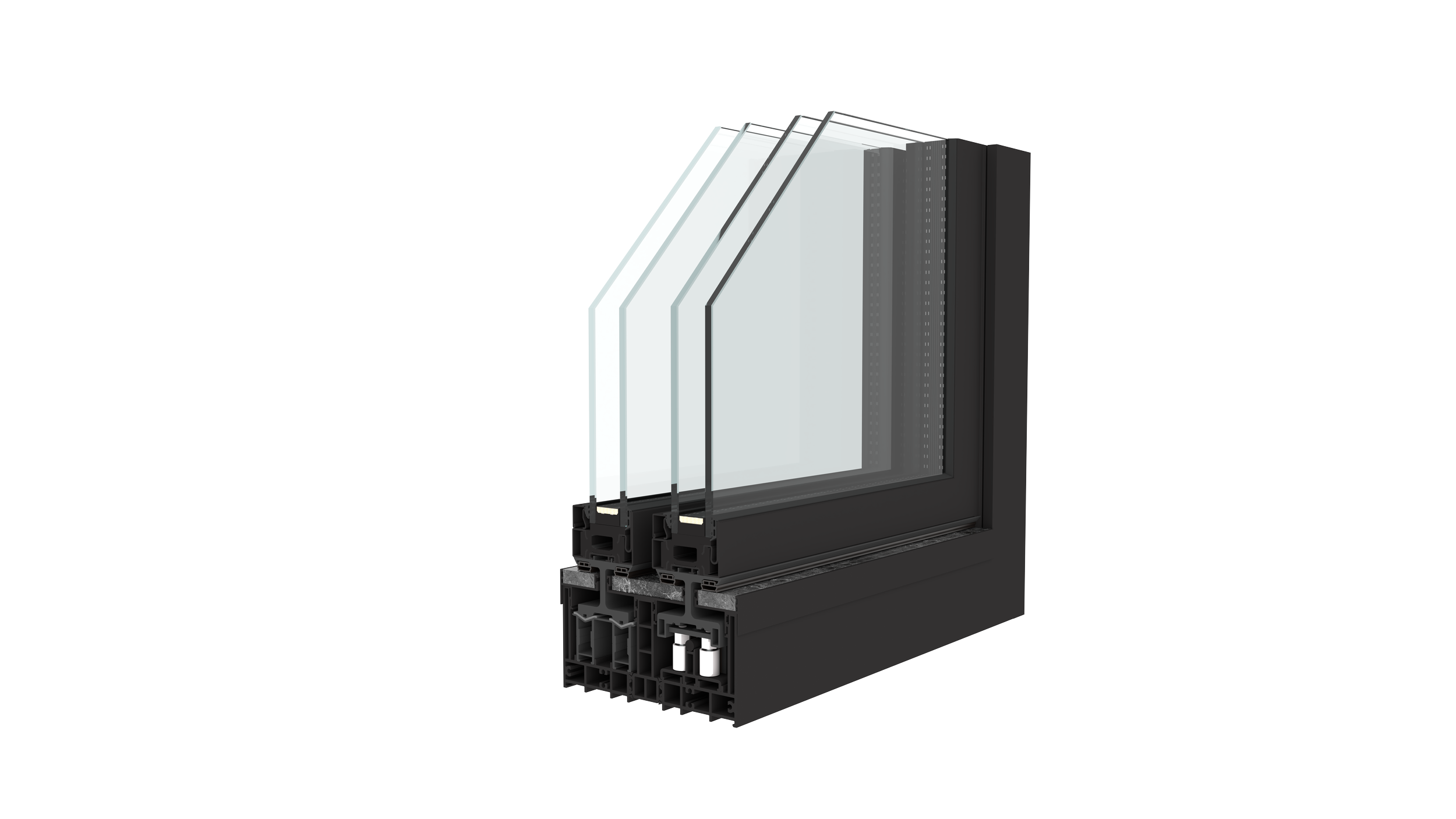

Thermally Broken

Our profile system delivers excellent thermal insulation by utilizing advanced pouring technology based on proven heat-insulation principles. It uses Azone polyurethane as the insulating material instead of the commonly used polyamide strips, resulting in superior performance. This solution is environmentally friendly, energy-efficient, and highly practical for real-world applications.

Features narrow frames with smaller viewing surfaces.

Steel profiles frame, low thermal conductivity, and high strength.

Customizable glazing bead with double or triple glazing up to 42mm.

Thermal conductivity (K) for Slim-65 is 1.6 W/(m2·K)

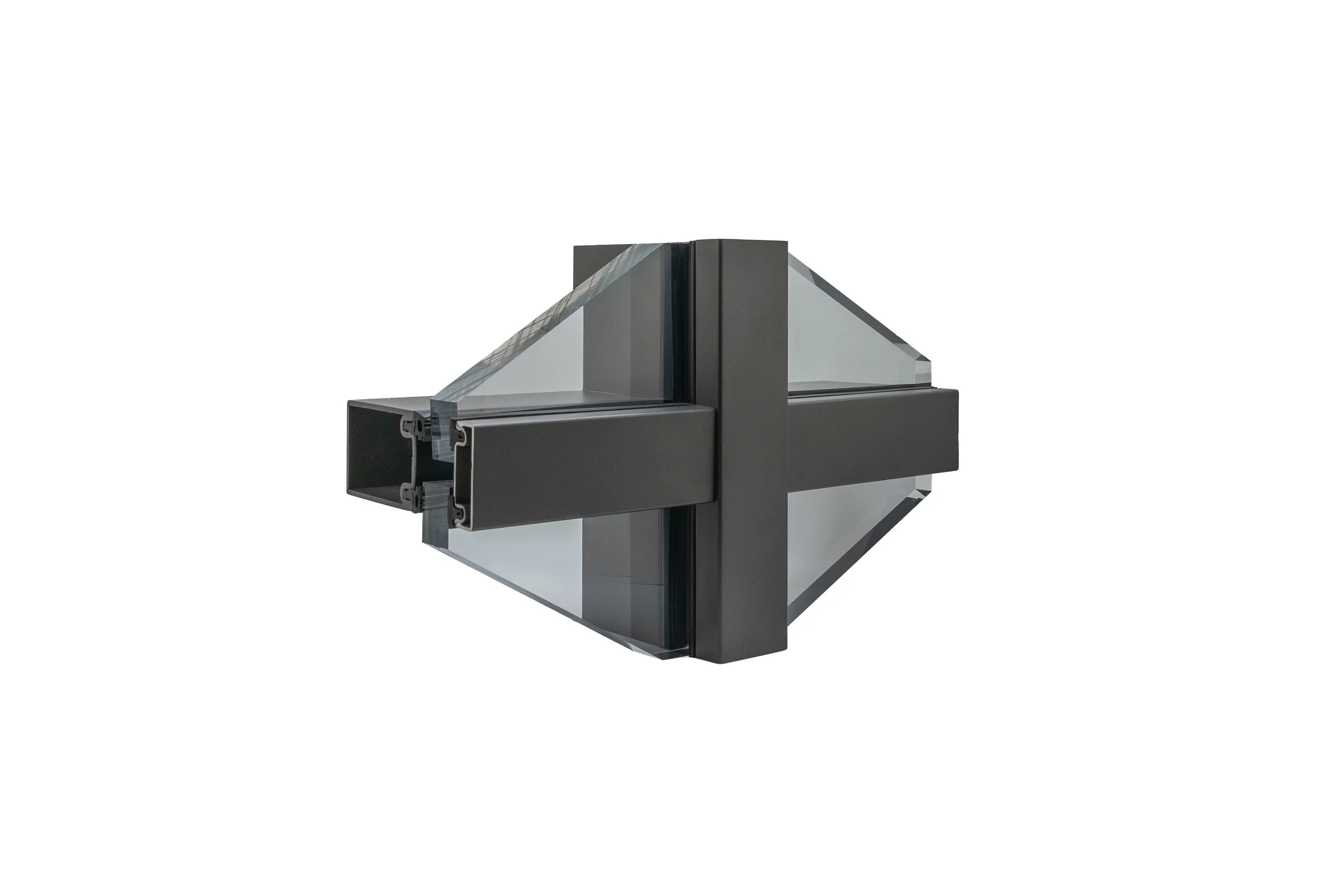

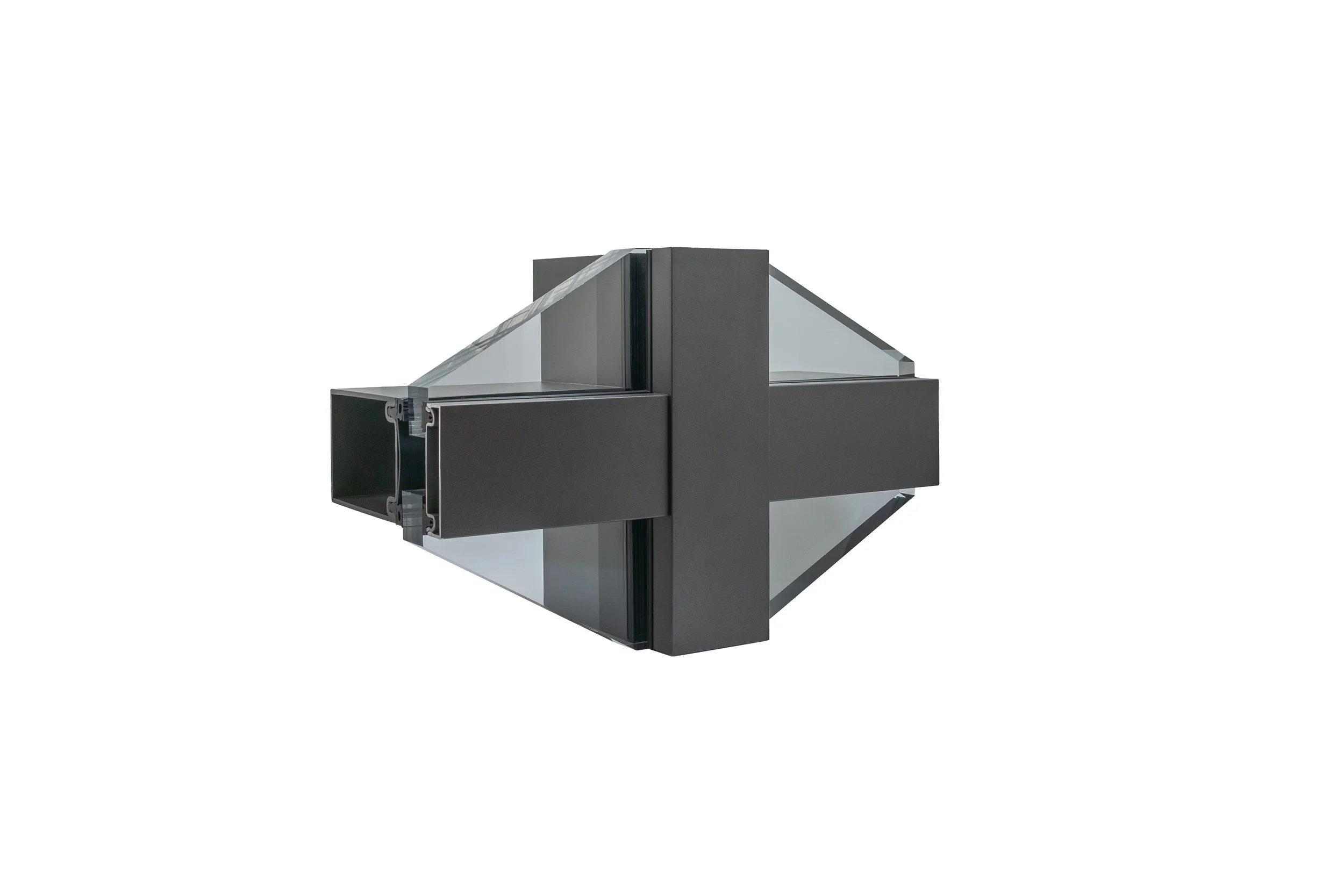

Fire Insulated

The profiles are crafted from specially shaped steel, with cold-rolled galvanized steel sheet serving as the raw material. This material undergoes automated production processes to form precision steel profiles. These production lines are engineered to create profiles with enhanced density, a high melting point, and other desirable characteristics. The resulting profiles offer significant advantages, including fire resistance, explosion resistance, low carbon content, and energy efficiency. Additionally, their structural integrity and solidity maximize the lighting area while minimizing the frame size. In fireproof applications, the integration of fireproof glass, sealing materials, and other components ensures compliance with fire resistance, integrity, and heat insulation requirements within a specified time frame.

Cold-formed steel profiles and glass fiber polyurethane heat-breaking composition of the new fireproof and heat-insulating profiles.

Depending on the cavity viewing surface, the system is available in 7055/7025.

Fire protection up to EI 90 min for 70SD, and EI 180 for ST60.

Excellent thermal insulation performance, with energy-saving glass achieving a K-value of

1.2 W (m2/K).With the injection process, better water-tightness is achieved when making windows.

Lightweight design, profile meter weight reduced by 20% compared to similar products.

More compatible hardwares are available for installation.